Min. Zamówienie:1 Piece/Pieces

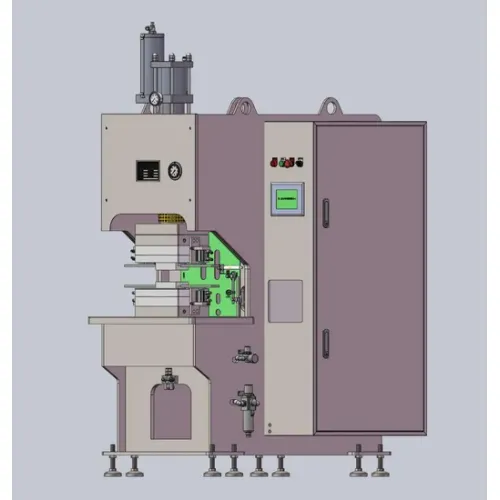

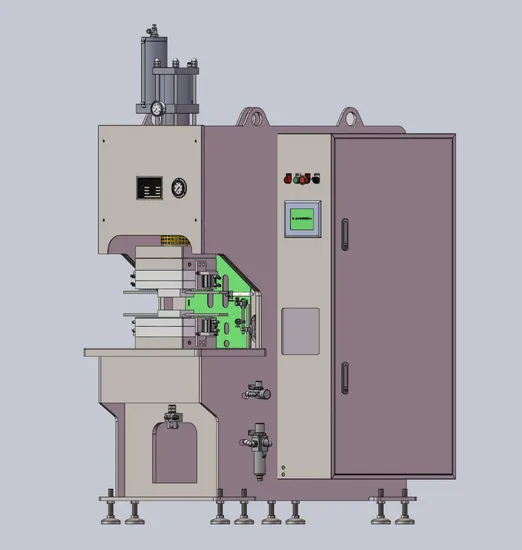

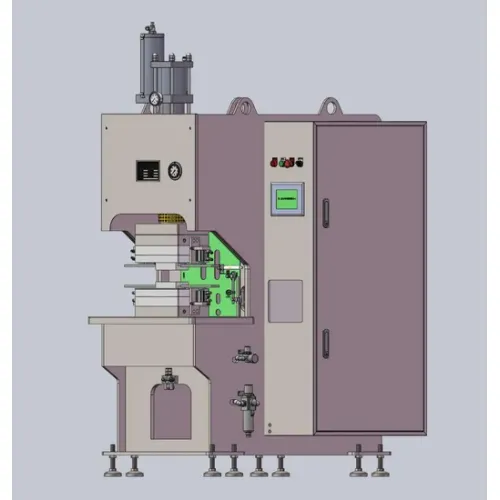

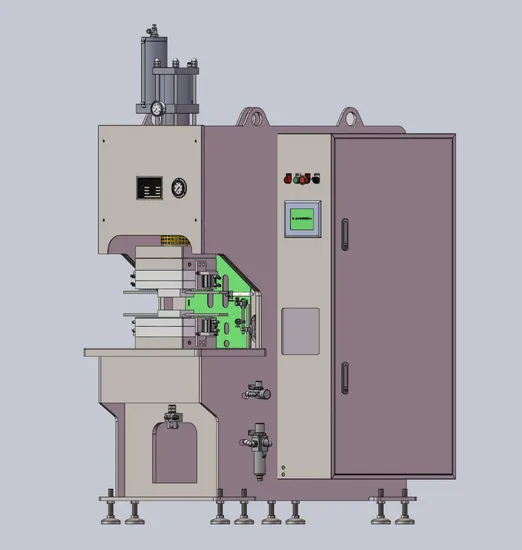

Style: Vertical

Shielding Gas: No

Electric Current: DC

Type: Diffusion Welding Machine

Transport Package: at Customer's Requrest

Specification: export standard

Trademark: xinchang

Origin: Ningbo China

Código HS: 84688000

Zdolność produkcyjna: 100 Sets/Month

Dostosowywanie: Available

Cooling Way: Water Cooling

Control: Semi-Automatic

Wsparcie: 100 Sets/Month

Cechy:

Zgrzewarka dyfuzyjna polimerów dzieli się na dwa typy: zgrzewarkę miedzianą i zgrzewarkę aluminiową. Jest to specjalna spawarka do produkcji pojazdów nowej energii, miękkich połączeń akumulatorów mocy i miękkich połączeń mocy. Jego zaletami są brak konieczności lutowania, bezśladowe spawanie i gładki wygląd obrabianego przedmiotu. Produkty są szeroko stosowane w nowych pojazdach energetycznych, bateriach zasilających, szafach rozdzielczych, transformatorach, instalacjach energetycznych i innych gałęziach przemysłu. Niezależnie opracowana i wyprodukowana przez naszą firmę zgrzewarka dyfuzyjna polimerów jest na wiodącym poziomie w Chinach. Produkt jest używany normalnie od wielu lat przez wiele firm w branży i cieszy się dobrymi opiniami użytkowników oraz dobrą opinią wśród krajowych producentów sprzętu spawalniczego.| 1 | Suitable for soft aluminum sheets welding, also capable of surface nickel welding, copper-aluminum welding, aluminum-aluminum welding. |

| 2 | Heating temperature:≥800ºC,Temperature measurement range:300ºC-1400ºC,Process accuracy:±3. Temperature, pressure, time, etc. can be adjusted and displayed on the touch screen . |

| 3 | The equipment mainly uses gas-liquid booster cylinders and precision pressure regulating valves to control the pressure to achieve the product welding process thickness tolerance requirements.. |

| 4 | Graphite installation area:130*80*70mm |

| 5 | Effective welding area:100*100mm (The product requirements of larger welding area can be achieved through segmented welding) |

| 5 | Electrode installation area:140mm*90mm |

| 6 | Welding material thickness:0.03mm-5mm |

| 7 | Welding product thickness:0.5mm-25mm |

| 8 | Cooling water requirements: The water flow rate requirement is 12m³/h, the head is 20 meters, or an equivalent booster pump can meet the mass production needs. Cooling water requirements:

|

| 9 | Aluminum foil meets batch single-piece peel strength≥3N/mm² |

| 10 | Digital hydraulic cylinder pressurization, max output pressure 10T,starting pressure 50KG,adjustment step unit 10Kg,set pressure accuracy within ±5% FS,welding accuracy ±0.1mm. Welding stability is determined by sir pressure. |

| 11 | C type vertical welding table |

| 12 | Power wiring:≥70mm2 Copper core wire, three-phase five-wire system. Incoming power requirements:

|

| 13 | High frequency heating, rated power 100KVA |

| 14 | Noise level below 65 decibels |

| 15 | Grey, close to RAL9010 paint |

| 16 | 1,The equipment is equipped with safety devices during operation, which can put the system into grounding state in any abnormal operation to ensure no high voltage load. 2,There are no obvious sharp parts on the outside of the device to prevent injuries to people during use. 3,Parts of the equipment that pose safety risks should be clearly marked, such as anti-electric shock sign and warning sign. 4,The equipment has the function of water temperature, water flow, current, voltage, and phase loss abnormal alarm and shutdown protection. |

| 17 |

3. The equipment must not misappropriate the protected patent technology of a third party. Party B shall be responsible for any disputes arising therefrom, and Party A shall not be responsible. |

| 18 | The equipment has functions such as quick release, quick change, graphite fixture, etc. |

1. P: A co ze standardową datą dostawy?

1. P: A co ze standardową datą dostawy?